|

|

DESCRIPTION:

These Hydraulic Clamping elements are pull type swing cylinders,

wherein a part of the total stroke is used to swing the arm (stroke to swing).

The shorter part is available as clamping stroke. These swing clamps are

having a special feature during the rotation (swing), it covers 20mm

stroke and thereafter it travels vertically for 10mm clamping stroke. The

total stroke is 30mm.

FEATURES:

- Min./ Max. Operating Pressure 10/250 bar.

- Large clamping range.

- Total stroke 30 mm. Swing stroke 20 mm. Vertical stroke 10 mm.

- Arm swing will be 90 2 .

- 360 adjustable arm location.

NOTE :

- Refer general design notes before selection &use.

- CW Model dimensions are same asCCWmodel dimensions.

- Refer accessories sheet page No. X1 & X2 for Clamp arm and ring

nut details.

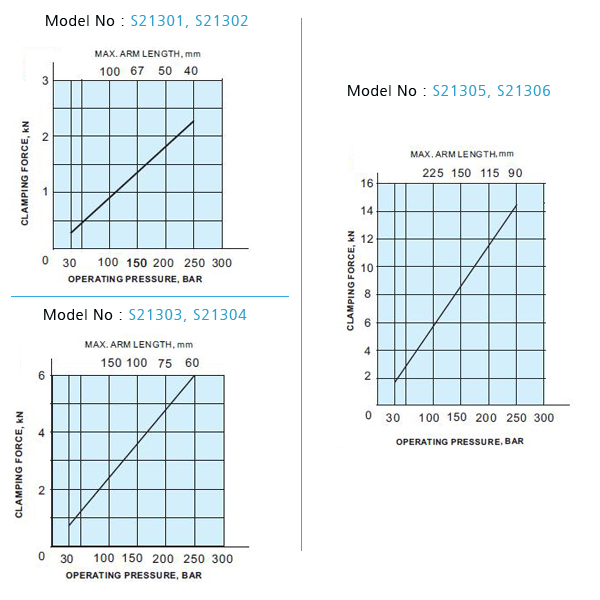

- Given forces are for the standard arm lever. Pressure and flow

should be reduced if clamp arm length is increased (Refer graph

sheet G1).

- Models with overload protection are available as special.

Dimensions are different. Contact : Quicloc.

- Ordering specification for seal kit. Add prefix "SK" to the model

Number.

|

- Actual clamping takes place when the Cylinder has

completed its 90 swing stroke.

- only

Clamping allowed only in clamping stroke not in swing

stroke.

- Do not exceed max. flow rate. If flow rates are exceeded,

swing cylinder indexing mechanism may be permanently

damaged.

- If the system flow rate

exceeds, use one way flow

control valve in the upstream

hydraulic lines.

- Length of Clamping arm,

weight of Clamping arm,

max. Permissible flow rate

and working pressure are all

important. Refer graphs for

arm length and working

pressure.

- Keep weight of Clamping

arm to a minimum.

|

|

GRAPH :

|

DESCRIPTION:

These Hydraulic Clamping elements are pull type cylinder, wherein a part

of the total stroke is used to swing the piston (stroke to swing). The

shorter part is available as clamping stroke. These swing clamps are

having a special feature during the rotation (swing, it covers 20mm

stroke and thereafter travels vertically for 10mm clamping stroke. The

total stroke is 30mm.

FEATURES:

- Min./ Max. Operating Pressure 10/250 bar.

- Large Clamping range.

- Total stroke 30 mm. Swing stroke 20 mm. Vertical stroke 10 mm.

- Arm swing will be 90 2

- 360 adjustable arm location.

NOTE :

- Refer general design notes before selection &use.

- CW Model dimensions are same asCCWmodel dimensions.

- Refer accessories sheet page No. X1 & X2 for Clamp arm and ring

nut details.

- Given forces are for the standard arm lever. Pressure and flow

should be reduced if clamp arm length is increased (Refer Graph

sheet No. G1).

- Models with overload protection are available as special.

- Dimensions are different. Contact Quicloc.

- Ordering specification for seal kit. Add prefix "SK" to the model

Number.