Bottom or Top Flange Mounted Swing Clamps |

|

DESCRIPTION:

Swing clamps can be chosen in two different mounting configurations namely bottom flange mounted swing clamp or top flange mounted swing clamp. The selection depends on the space available and the clamping points available in the design of your machine. These Hydraulic Clamping elements are pull type swing cylinders, wherein a part of the total stroke is used to swing the arm (stroke to swing). The shorter part is available as clamping stroke. These swing clamps are having a special feature during the rotation (swing), it covers 20mm stroke and thereafter it travels vertically for 10mm clamping stroke. The total stroke is 30mm.

In case of need for further customization or discussion regarding the top and bottom flange mounting please contact us. We would be happy to help your find the right swing clamp configuration for you.

FEATURES:

- Min./Max. Operating Pressure 10/250 bar.

- Large clamping range.

- Total stroke 30 mm. Swing stroke 20 mm. Vertical stroke 10 mm.

- Arm swing will be 90 2

- 360 adjustable arm location.

NOTE :

- Refer general design notes before selection &use.

- CWModel dimensions are same asCCWmodel dimensions.

- Refer accessories sheet page No. X2 for clamp arm details.

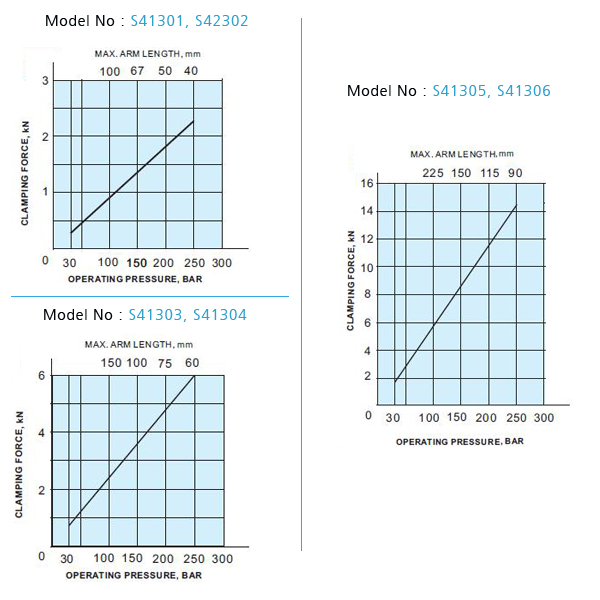

- Given forces are for the standard arm lever. Pressure and flow

should be reduced if clamp arm length is increased (Refer Graph

sheet No. G1).

- Ordering specification for seal kit. Add prefix "SK" to the model

Number.

- Actual clamping takes place when the

Cylinder has completed its 90 swing stroke.

- Only

Clamping allowed only in clamping stroke not in

swing stroke.

- Do not exceed max. flow rate. If flow rates are

exceeded, swing cylinder indexing mechanism

may be permanently damaged.

- If the system flow rate

exceeds, use one way

flow control valve in the

upstream hydraulic lines.

- Length of Clamping arm,

weight of Clamping arm,

max. Permissible flow

rate and working pressure

are all important. Refer

graphs for arm length and

working pressure.

- Keep weight of Clamping

arm to a minimum.

GRAPH :

|

SPECIFICATION CHART

All dimensions in mm.

| Model No. : CW |

S41301 |

S41303 |

S41305 |

| CCW |

S41302 |

S41304 |

S41306 |

| Force F kN @ 100 bar |

1 |

2.6 |

6.3 |

| @ 200 bar |

1.9 |

5.3 |

12.6 |

| Piston dia /RodØd |

25 / 20 |

40 / 32 |

63 / 50 |

| Stroke: Swing stroke |

20 |

20 |

20 |

| Vertical stoke |

10 |

10 |

10 |

| Oil Volume cc |

5.3 |

13.5 |

34.6 |

| M1 x Pitch |

M16x1.5 |

M24x1.5 |

M33x2 |

| Ød1 |

22 |

33 |

52 |

| Ød2 |

48 |

65 |

90 |

| L + 0.5 |

174 |

200 |

225 |

| L1 |

112 |

132 |

145 |

| L2 |

87 |

107 |

120 |

| L3 |

116 |

136 |

149 |

| L4 |

16 |

20 |

26 |

| L5 |

12 |

14 |

20 |

| L6 |

10 |

12 |

18 |

| L7 |

7 |

8 |

10 |

| B |

68 |

90 |

127 |

| B1 |

30.5 |

39 |

54 |

| B2 |

58 |

78 |

108 |

| B3 |

42 |

60 |

82 |

| B4 |

29 |

39 |

54 |

| B5 |

53 |

73 |

101 |

| B6 |

22.5 |

30 |

41 |

| G |

1/8" |

1/4" |

1/4" |

| A/F |

26 |

42 |

60 |

| ØM x deep |

14.5x10 |

19x14 |

26x18 |

| ØN |

9 |

14 |

18 |

| Max. flow rate lpm |

0.15 |

0.6 |

1.6 |

| Std. clamp arm |

XS2501 |

XS4001 |

XS6301 |

Specifications subject to improvements.

Click here to download a pdf:

S41301-02 | S41303-04 | S41305-06

DESCRIPTION:

These Hydraulic Clamping elements are pull type cylinder, wherein a part

of the total stroke is used to swing the piston (stroke to swing). The shorter

part is available as clamping stroke. These swing clamps are having a

special feature during the rotation (swing), it covers 20mm stroke and

thereafter travels vertically for 10mm clamping stroke. The total stroke is

30mm.

FEATURES:

- Min./ Max. Operating Pressure 10/250 bar.

- Large clamping range.

- Total stroke 30 mm. Swing stroke 20 mm. Vertical stroke 10 mm

- Arm swing will be 90 2.

- 360 adjustable arm location.

NOTE :

- Refer general design notes before selection & use.

- CW Model dimensions are same as CCW model dimensions./

- Refer accessories sheet page No. X2 for clamp arm details.

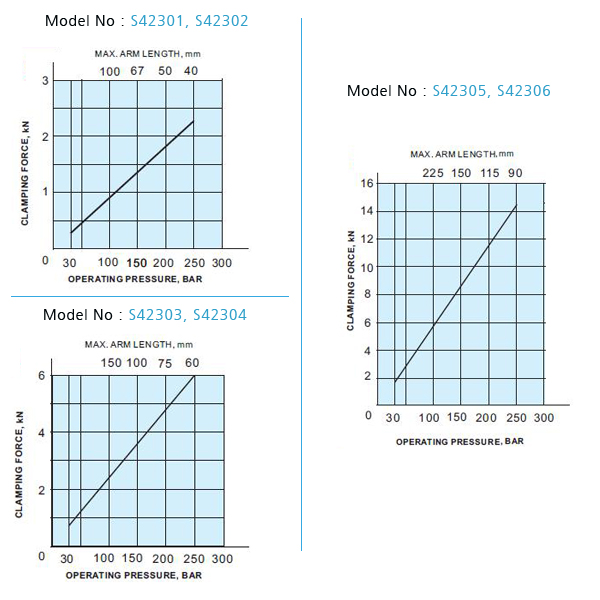

- Given forces are for the standard arm lever. Pressure & flow

should be reduced if clamp arm length is increased (Refer Graph

sheet No. G1).

- Models with overload protection are available as special.

- Dimensions are different. Contact Quicloc.

- Ordering specification for seal kit. Add prefix "SK" to the model

Number.

- Actual clamping takes place when the

Cylinder has completed its 90 swing stroke.

- only

Clamping allowed only in clamping stroke not in

swing stroke.

- Do not exceed max. flow rate. If flow rates are

exceeded, swing cylinder indexing mechanism

may be permanently damaged.

- If the system flow rate

exceeds, use one way

flow control valve in the

upstream hydraulic lines.

- Length of Clamping arm,

weight of Clamping arm,

max. Permissible flow

rate and working pressure

are all important. Refer

graphs for arm length and

working pressure.

- Keep weight of Clamping

arm to a minimum.

GRAPH :

|

SPECIFICATION CHART

All dimensions in mm.

| Model No. : CW |

S42301 |

S42303 |

S42305 |

| CCW |

S42302 |

S42304 |

S42306 |

| Force F kN @ 100 bar |

1 |

2.6 |

6.3 |

| @ 200 bar |

1.9 |

5.3 |

12.6 |

| Piston dia /RodØd |

25 / 20 |

40 / 32 |

63 / 50 |

| Stroke: Swing stroke |

20 |

20 |

20 |

| Vertical stoke |

10 |

10 |

10 |

| Oil Volume cc |

5.3 |

13.5 |

34.6 |

| M1 x Pitch |

M16x1.5 |

M24x1.5 |

M33x2 |

| Ød1 |

22 |

33 |

52 |

| Ød2 |

48 |

65 |

90 |

| L ± 0.5 |

174 |

200 |

225 |

| L1 |

112 |

132 |

145 |

| L2 |

116 |

136 |

149 |

| L3 |

20 |

22 |

22 |

| L4 |

12 |

14 |

20 |

| L5 |

16 |

20 |

26 |

| L6 |

10 |

12 |

18 |

| L7 |

7 |

8 |

10 |

| B |

68 |

90 |

127 |

| B1 |

30.5 |

39 |

54 |

| B2 |

58 |

78 |

108 |

| B3 |

42 |

60 |

82 |

| B4 |

29 |

39 |

54 |

| B5 |

53 |

73 |

101 |

| B6 |

22.5 |

30 |

41 |

| G |

1/8" |

1/4" |

1/4" |

| A/F |

26 |

42 |

60 |

| ØN |

9 |

14 |

18 |

| Max. flow rate lpm |

0.15 |

0.6 |

1.6 |

| Std. clamp arm |

XS2501 |

XS4001 |

XS6301 |

Specifications subject to improvements.

Click here to download a pdf:

S42301-02 | S42303-04 | S42305-06

DESCRIPTION:

These Hydraulic Clamping elements are pull type swing cylinders, wherein a part of the total stroke is used to swing the arm (stroke to swing). The shorter part is available as clamping stroke. These swing clamps are having a special feature during the rotation (Swing), it covers 10 mm stroke and thereafter it travels vertically for 14 mm clamping stroke. The total stroke is 24 mm.

FEATURES:

- Min/Max. operating pressure 20/1 80 bar.

- Large clamping range.

- Double acting ranges.

- Very compact cylinder design.

- 360 adjustable arm location.

- Arm swing will be 90c± 0.2°

- Total stroke 24mm. Swing Stroke 10 mm.

- Clamp stroke 14 mm

NOTE :

- Refer general design notes before selection & use.

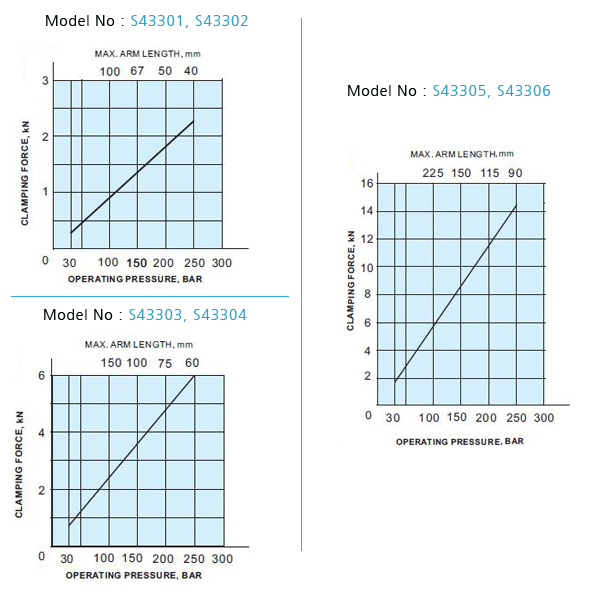

- Given forces are for the standard arm lever.

- Pressure and flow should be reduced if clamp arm length is increased (Refer catalog graph sheet No.-G1) Ordering specification for seal kit.

- Add prefix SK" to the model Number.

- If the system flow rate exceeds, use one way flow control valve in the upstream hydraulic lines.

- Length of Clamping arm, weight of Clamping arm, max. Permissible flow rate and working pressure are all important.

- Refer graphs for arm length and working pressure.

- Keep weight of clamping arm to a minimum.

- Actual clamping takes place only when the Cylinder has completed its 900 swing stroke.

- Clamping allowed only in clamping stroke not in swing stroke.

- Do not exceed max. flow rate. If flow rates are exceeded, swing cylinder indexing mechanism may be permanently damaged.

GRAPH :

|

| Part No |

a |

c |

b |

g |

h |

d1 |

d |

M |

e |

d |

| XS4003 |

115 |

75 |

26 |

23 |

18 |

34 |

31.8 |

M16 |

23 |

52 |

| XS5003 |

144 |

100 |

30 |

34 |

28 |

45.5 |

39.8 |

M16 |

26 |

60 |

| XS6303 |

178 |

120 |

40 |

34 |

28 |

56 |

49.8 |

M20 |

40 |

78 |

SPECIFICATION CHART

All dimensions in mm.

| Model No. : CW |

S43301 |

S43303 |

S43305 |

| CCW |

S43302 |

S43304 |

S43306 |

| Force F kN @ 100 bar |

7KN |

10KN |

17KN |

| Piston dia /RodØd |

40 / 20 |

50/40 |

63/50 |

| Oil Vol.clamp |

11cc |

18cc |

28cc |

| Oil Vol.clamp |

30cc |

48cc |

75cc |

| Swing stroke/Clamp stroke |

10/14 |

10/14 |

10/14 |

| M1 x Pitch |

M28x1.5P |

M36x1.5P |

M46x2P |

| Ød1 |

32 |

40 |

50 |

| Ød2 |

60 |

75 |

90 |

| L |

129 |

160 |

160 |

| L1 |

97 |

116 |

116 |

| L2 |

52 |

67 |

67 |

| L3 |

101 |

120 |

120 |

| T |

16.5 |

15.5 |

18 |

| B-SQ |

75 |

85 |

105 |

| B3-SQ |

60 |

65 |

80 |

| ØN |

11 |

11 |

17 |

| Max. flow rate lpm |

0.6 |

1 |

1.6 |

Specifications subject to improvements.

Click here to download a pdf:

S43301-02 | S43303-04 | S43305-06

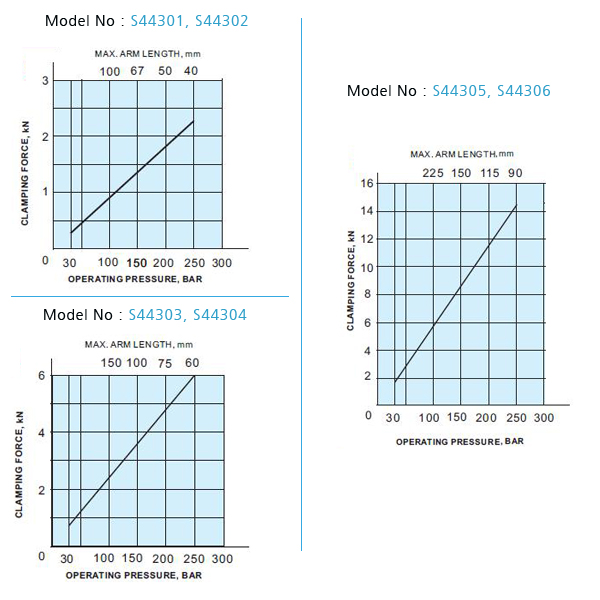

- If the system flow rate exceeds, use one way flow control

valve in the upstream hydraulic lines.

- Length of Clamping arm, weight of Clamping arm, Max.

Permissible flow rate and working pressure are all

important. Refer graphs for arm length and working

pressure.

- Keep weight of Clamping arm to a minimum.

DESCRIPTION:

These Hydraulic Clamping elements are pull type swing

cylinders, wherein a part of the total stroke is used to swing

the arm (stroke to swing). The shorter part is available as

clamping stroke. These swing clamps are having a special

feature during the rotation (swing), it covers 10 mm stroke

and thereafter it travels vetically for 14 mm clamping stroke.

The total stroke is 24 mm.

FEATURES:

- Min/Max. Operating Pressure 20/180 bar.

- Large clamping range

- Double acting ranges

- Very compact cylinder design

- 360 adjustable arm location

- Arm swing will be 90 + 0.2

- Total stroke 24mm. Swing stroke 10 mm. Clamp stroke

14 mm

NOTE :

- Refer general design notes before selection & use.

- Given forces are for the standard arm lever. Pressure

and flow should be reduced if clamp arm length is

increased (Refer catalog graph sheet No.-G)

- Ordering specification for seal kit. Add prefix "SK" to

the model Number.

- Actual clamping

takes place

when the Cylinder

has completed its 90

swing stroke.

- Only

Clamping allowed

only in clamping

stroke not in swing

stroke.

- Do not exceed max.

flow rate. If flow rates

are exceeded, swing

cylinder indexing

mechanism may be

p e r m a n e n t l y

damaged.

GRAPH :

|

| Part No |

a |

c |

b |

g |

h |

d1 |

d |

M |

e |

d |

| XS4003 |

115 |

75 |

26 |

23 |

18 |

34 |

31.8 |

M16 |

23 |

52 |

| XS5003 |

144 |

100 |

30 |

34 |

28 |

45.5 |

39.8 |

M16 |

26 |

60 |

| XS6303 |

178 |

120 |

40 |

34 |

28 |

56 |

49.8 |

M20 |

40 |

78 |

SPECIFICATION CHART

All dimensions in mm.

| Model No. : CW |

S44301 |

S44303 |

S44305 |

| CCW |

S44302 |

S44304 |

S44306 |

| Force F kN @ 100 bar |

7KN |

10KN |

17KN |

| Piston dia /RodØd |

40 / 32 |

50/40 |

63/50 |

| Oil Vol.clamp |

11cc |

18cc |

28cc |

| Oil Vol.clamp |

30cc |

48cc |

75cc |

| Swing stroke/Clamp stroke |

10/14 |

10/14 |

10/14 |

| M1 x Pitch |

M28x1.5P |

M36x1.5P |

M46x2P |

| Ød1 |

32 |

40 |

50 |

| Ød2 |

60 |

75 |

90 |

| L |

129 |

160 |

160 |

| L1 |

97 |

116 |

116 |

| L2 |

52 |

67 |

67 |

| L3 |

101 |

120 |

120 |

| T |

16.5 |

15.5 |

18 |

| B-SQ |

75 |

85 |

105 |

| B3-SQ |

60 |

65 |

80 |

| ØN |

11 |

11 |

17 |

| Max. flow rate lpm |

0.6 |

1 |

1.6 |

Specifications subject to improvements.

Click here to download a pdf:

S44301-02 | S44303-04 | S44305-06

|

|